Shipping and fulfillment are like the sound equipment at a concert. When it works correctly, no one thinks about how it works or what’s happening behind the scenes. However, a malfunction is instantly disruptive and can ruin the experience if unresolved.

Ecommerce shipping delays are frustrating for everyone: you, your customer, and the carrier responsible for delivering the shipment. Here are seven problems that often delay shipments.

7 Common Issues That Cause Shipping Delays

Do any of these issues sound familiar?

1. Need to fulfill and ship orders faster – Streamline your warehouse layout and workflows.

2. Missing daily carrier pickup time – Fulfill and ship ecommerce orders faster.

3. Tedious, error-prone manual tasks – Eliminate repetitive, labor-intensive tasks and mistakes.

4. Poor inventory visibility and overselling – Use software to manage inventory and keep your web store updated.

5. Lost or stolen packages – Use shipping insurance to cover lost or stolen items.

6. Shipping to unverifiable addresses – Use shipping software with address verification technology.

7. Incorrect customs documents for international shipping – Use templates to file customs documents correctly.

The good news is that you can often avoid common shipping issues with a little know-how, the right software, and a few tweaks to your fulfillment ops. Here are seven tips to prevent shipping delays.

Shipping Tip 1: Streamline your warehouse layout and fulfillment workflows.

Ecommerce Shipping Issue: Need to fulfill and ship orders faster

As an online retailer, managing growing order volumes can feel overwhelming, especially during peak seasons. Late deliveries and backlogs happen when you’re unable to keep up. If your warehouse is disorganized, finding the right items can turn into a frustrating treasure hunt. Many businesses still rely on paper-based processes, which are slow and prone to errors.

Instead of hiring more staff, which may not be a sustainable long-term solution, consider implementing shipping technology. Automation reduces bottlenecks and keeps your fulfillment operations running smoothly, even during the busiest times. By using these solutions, you’ll not only meet customer expectations but also maintain your competitive edge in the market.

BW Retail Solutions team recently solved this problem by making smart changes to their strategy and warehouse management. They started by upgrading workflows for inventory management, order fulfillment, and shipping. By using a fully integrated warehouse management system plus shipping software, the shipping team reduced bottlenecks to fulfill and ship orders faster. They also redesigned the warehouse layout to improve picking speed and storage. The new layout made it easier for workers to move around and stay safe.

After making the switch from paper-based processes to a WMS + shipping software, warehouse managers reported up to 4x greater throughput. See how BW Retail solved this problem.

How can I fulfill and ship orders faster?

The truth is there are many aspects of throughput within your control, especially with the shipping technology available today. The best way to fulfill and ship orders faster is to increase the speed and accuracy of your pick-pack-ship process with a warehouse management system and shipping software.

JOELLE, a popular Canadian brand for women’s designer clothing and accessories, used this approach to overcome similar fulfillment challenges.

JOELLE faced overwhelming order volumes that slowed down their fulfillment processes. During peak seasons, JOELLE struggled with labor shortages and backlog issues. They relied on outdated, paper-based processes that were prone to errors. By transitioning to a cloud-based WMS and shipping software solution they managed seasonal spikes without needing additional staff.

Before integration, JOELLE’s warehouse was disorganized, staff were wasting time searching for items. With real-time inventory visibility and barcode scanning, they updated their pick-pack-ship process, to make it easy to locate products quickly.

Shipping Tip 2: Meet your scheduled carrier pickup time.

Ecommerce Shipping Issue: Missing the pickup time and shipping orders late

When peak seasons hit and order volume spikes, internal order processing delays cause a bottleneck at the shipping station, causing you to miss your scheduled carrier pickup time.

Online retailer eCard Systems faced this problem. The manual process to select the correct service and package type for each order bogged down warehouse productivity and limited the company’s ability to grow their business.

Despite their best efforts, the company struggled to keep up with labeling. When peak volumes hit, the slow process caused them to risk missing FedEx pickup cutoffs during the busiest times. See how eCard systems solved this problem.

How can I stop missing my scheduled pickup time?

To stop missing carrier pickups, you can adjust two main factors: carrier pickup time/frequency and processing speed for packing and preparing your orders for shipment.

Change your pickup time/frequency

You can work directly with your carrier to change your scheduled pickup time or add extra pickups if it makes sense. Contact your carrier representative, explain the situation, and ask for different options to accommodate your business needs.

Pack and ship orders faster

To increase processing speed, choose the best shipping software for your business to easily scale operations during peak seasons and spikes in ecommerce order volume. That way, you can keep up with orders as they come in, processing a greater number of shipments with the same number of workers. By preventing bottlenecks in the shipping process, you can ensure that all orders are packed and labeled for shipping ahead of your scheduled pickup time.

Specifically, shipping software uses automation rules to eliminate manual tasks such as typing order/address information, selecting the right shipping service, entering package dimensions, rate shopping to find the best shipping rates, emailing customers their tracking information, updating orders with tracking information, and much more.

Tip 3: Eliminate repetitive, labor-intensive tasks and human errors.

Ecommerce Shipping Issue: Slow and Error-Prone Manual Processes

Does your fulfillment process rely on time-consuming, hands-on procedures such as manually typing in shipping information, selecting shipping services, entering package information, and emailing customers their tracking info? What happens when order volumes spike during sales or peak seasons? If backlogged orders are piling up next to your ship station, manual processes and labor shortage are the likely causes.

Relying on outdated manual systems slows down your warehouse operations. When your logistics management, shipping, and fulfillment processes lack technology integration, mistakes can easily occur. This outdated approach leads to time-consuming manual tasks, such as:

- Typing shipping information: Increases the risk of typos and mis-ships.

- Selecting shipping services: Consumes valuable time and may require expertise.

- Entering package details: Leaves room for mistakes that can delay shipments.

- Emailing tracking information to customers: Can result in miscommunication.

If the shipping process is slow on a normal day, what happens during sales spikes of increased order volumes? Warehouse workers often scramble to prepare shipments before carrier pickups. Avoid this chaos by implementing a comprehensive, end-to-end shipping strategy that incorporates automation. Here are ideas for how online retailers can prepare for peak seasons.

How can I reduce repetitive tasks and human errors?

As a mid-sized ecommerce business or wholesale distributor, you can streamline your operations and minimize errors with these shipping strategies:

- Shipping Automation Rules: Say goodbye to manual processes! Automation rules take over routine tasks, like selecting shipping methods and generating labels. This saves time and also reduces the risk of human errors.

- Shipping Integrations: Integrate your shipping software with other business systems. This means you won’t have to worry about inaccurate information from manual data entry. It keeps your data consistent and up to date.

- Barcode Scanning with WMS: Include barcode scanning in your warehouse management system (WMS). It simplifies inventory management for accurate order picking. By reducing errors, you’ll improve your overall efficiency and ensure that your customers receive their orders on time.

Replace manual processes with automation rules that handle routine tasks, such as selecting shipping methods and generating labels. You can speed up order processing with pre-set requirements, like package size and shipping costs. Automation is not a luxury; it’s a necessity for staying competitive in today’s fast-paced ecommerce landscape.

Recently, eCard Systems solved this problem by automating their operations and reduced processing time from 30 seconds to just 10 seconds per order. Warehouse and fulfillment managers no longer need to rely solely on their most experienced team members for data entry. The system handles it, freeing up staff and resources for other tasks.

Tip 4: Improve inventory visibility and keep your web store updated.

Ecommerce Shipping Issue: Poor inventory visibility and overselling

As a mid-sized ecommerce retailer or wholesale distributor, you know how important it is to have a clear view of your inventory. When visibility is low, overselling leads to frustrated customers and lost sales. You might find yourself facing challenges such as:

- Limited Inventory Awareness: Not knowing how much stock you have or where items are located in your warehouse negatively affects your logistics, warehouse, and shipping operations.

- Inefficient Manual Checks: Reliance on visual scans of shelves to track inventory wastes time and leads to mistakes.

- Outdated Online Store Data: If your ecommerce platform isn’t synced with real-time inventory levels, you risk selling items you don’t actually have, leading to backorders, cancellations, and unhappy customers.

How can I improve inventory visibility and stop overselling?

You can get greater control over inventory visibility with an inventory management system (IMS), order management system (OMS), or enterprise resource planning (ERP) program integrated with shipping software, a warehouse management system (WMS), and all your sales channels. This integrated ecommerce tech stack updates your store’s inventory and communicates order information to the warehouse, keeping everything in sync and minimizing errors.

State & Liberty solved this problem by using an integrated tech stack with Descartes ShipRush, Descartes Peoplevox WMS, Brightpearl OMS, and Loop returns to achieve a massive operational improvement with their integrated system, achieving 75% faster picking times and using 67% less labor, all while maintaining 95% order accuracy.

State & Liberty performed cycle counts using this system through their pick faces. Knowing precisely where each item was stored reduced the time spent searching for products for an optimized fulfillment process.

Tip 5: Cover lost or stolen items with shipping insurance.

Shipping Issue: Customer’s order is lost or stolen in transit.

Imagine the disappointment of ordering a long-awaited item online only to have it lost in transit or stolen from your doorstep! With around 260 million packages stolen in the United States last year, it’s clear why 81% of people consider delivery security extremely important, according to a recent consumer sentiment study (The Descartes Systems Group, Inc., 2024).

Porch piracy is a concern for online retailers. If a package is stolen, you lose out on revenue and end up with dissatisfied customers unless you use shipping insurance that covers package theft. Similarly, lost packages are covered by some types of ecommerce shipping protection but not others. Let’s look at the different types of coverage.

Types of Ecommerce Shipping Protection

Parcel protection is a non-negotiable for online retailers, and certain types of coverage are free. However, it’s essential to understand the difference between carrier liability coverage, often referred to as declared value coverage, and ecommerce shipping insurance.

There are a few types of parcel protection available to shield your business from risks associated with damage, theft, and loss:

- Free Declared Value Coverage: Carriers offer this basic protection at no extra cost, making it a suitable choice for small businesses on a tight budget. It usually covers up to $100 of declared value and only pays for damages if you can prove the carrier was at fault.

- Paid Declared Value Coverage: This option provides higher coverage limits for packages damaged in transit but requires proof of carrier negligence for reimbursement. It does not usually cover package loss or theft.

- Third-Party Shipping Insurance: With comprehensive protection against damage, theft, and loss, this insurance also typically offers faster claims processing than declared value coverage.

How can I resolve delays caused by lost or stolen packages?

As an online retailer, you need to quickly resolve delays from lost or stolen packages to give your customers a positive shipping experience. Investing in third-party shipping insurance is the best move. It helps safeguard all your shipments and processes claims faster than carriers.

Comprehensive Coverage

Third-party shipping insurance provides broader coverage than carrier liability. Coverage often includes high-value items, fragile products, lost packages, and parcel theft. This extra layer of security is essential for minimizing losses.

Fast Track Claims

Many third-party insurance providers offer quick claims processes, even during the holidays and other peak shipping periods. This way, your customers can get reimbursed faster and are less likely to have a negative experience with ordering from your brand.

Protect Your Profits

Lost packages, damaged goods, and theft can hurt your bottom line. With third-party shipping insurance, you reduce these losses. Parcel protection is a core aspect of the long-term success of an ecommerce business.

Tip 6: Use shipping software with address verification technology.

Shipping Issue: Shipping to unverifiable addresses

Online retailers must verify that each shipping address matches the correct destination address in the carrier’s system. Otherwise, the package may get delivered to the wrong location or returned to the sender, resulting in shipping delays and unhappy customers.

What is Address verification technology?

Address verification is a feature in shipping software used to confirm the accuracy of customer addresses for parcel shipping before a shipping label can be printed. Using an API, the shipping solution checks each address against the carrier’s delivery system or authoritative database and identifies errors.

How can I make sure all addresses are verifiable for my shipments?

Integrate your sales channels with shipping software that uses address verification technology to import and check order information, prevent typos, and eliminate manual data entry of shipping addresses.

If the customer’s shipping address is unverifiable, the shipping software will flag the address for your attention. The shipping address is then corrected (for example, an invalid zip code or poorly formatted street name is fixed), preventing a mis-ship and improving the overall shipping experience in-house and for customers.

Using a shipping solution with address verification technology, you can:

- Find and Correct Errors: Automatically flag unvalidated addresses and update them according to an authoritative database.

- Prevent Mis-Ships: Fewer packages will be delivered to the wrong location or returned to your business for re-shipment.

- Meet Customer Expectations: Prevent late deliveries, disappointment, negative reviews, and loss of repeat business.

- Save on Shipping Costs: Avoid the costs associated with late deliveries, re-shipping, and customer service issues.

- Optimize Shipping Efficiency: Streamline your shipping process by reducing the time spent on manual address verification and finding errors.

Tip 7: Use templates to file customs documents correctly

Shipping Issue: Incorrect customs documents cause international shipping delays

Imagine your ecommerce business is booming, and you’re ready to start selling your products internationally. For new international shippers, the complexity of international shipping paperwork can pose a challenge. Incorrect customs documents lead to shipping delays.

Shipments can get stuck in customs or returned to the sender if the shipper fails to include an accurate product description and harmonized tariff system (HTS) code for each product in the commercial invoice.

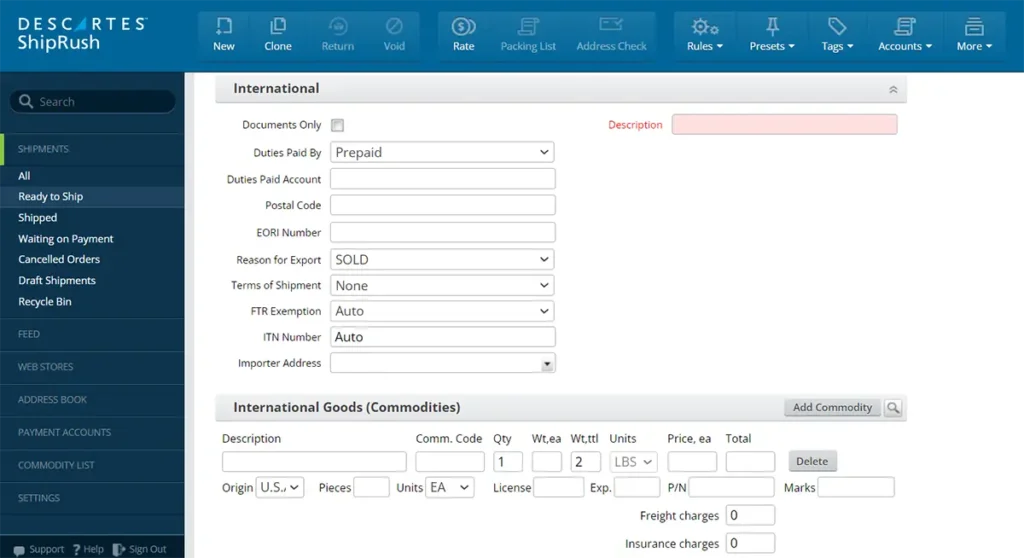

How can I file international shipping documents correctly?

Thankfully, advanced shipping software simplifies the process with helpful templates for international customs documentation. Beyond templates, some shipping solutions such as Descartes XPS automatically file certain customs documents for you. The electronic trade document handling feature eliminates the hassle of filing paperwork manually, saving you valuable time and reducing the risk of errors.

Wizard Distribution, a Michigan-based ecommerce company and international seller, used shipping software to overcome international shipping challenges so they could focus on growing their business instead of getting lost in paperwork. See how Wizard Distribution solved international shipping problems.

Key Takeaways

- Many ecommerce shipping delays are preventable, and it’s worth the effort to avoid them.

- Increase on-time deliveries and customer satisfaction by adjusting your shipping operations.

- Review ecommerce shipping case studies to learn how others solved similar problems.

About the Author

Mikel Richardson is a General Manager at Descartes, the global leader in providing on-demand, software-as-a-service solutions focused on improving the productivity, performance and security of logistics-intensive businesses. As GM of the ecommerce division, Mikel helps ecommerce brands grow wherever they are in their journey, whether shipping their first order or scaling internationally.