Table of Contents

- What is warehouse shipping software?

- What is a warehouse management system (WMS)?

- How do a WMS and shipping software work together?

- Do I need a shipping solution for my warehouse?

- How does warehouse shipping software reduce costs?

- Key Takeaways

- Can I request a shipping software demo?

Imagine what it would be like to run a stress-free warehouse where every ecommerce order makes it to the right customer on time. What if members of your team could focus on other tasks in the business, such as marketing, expansion, and customer service, instead of being buried in orders during busy peak seasons like Black Friday and the holidays?

In a world where shipping and fulfillment are fast-paced and require a lot of time and resources, warehouse shipping software can help streamline your process. Let’s dive into what warehouse shipping software is and how it can improve the ecommerce shipping experience for your business and your customers.

What is warehouse shipping software?

Warehouse shipping software is a program that warehouses use to increase speed and accuracy in shipping workflows while reducing costs. It connects to other programs such as sales channels, carrier accounts, warehouse management systems (WMS), inventory management systems (IMS), enterprise resource planning (ERP) programs like NetSuite®, and accounting/CRMs like QuickBooks.

This interconnectivity between the shipping solution and other programs reduces errors and increases throughput as data flows from one program to another. It also enables sophisticated business rules-based automation to eliminate tedious manual processes and reduce labor costs.

Which types of businesses use it?

Warehouse shipping software is often used by midsized ecommerce businesses or wholesale distributors who manage at least 1-3 warehouses. Potential industries could include ecommerce companies, manufacturers, food and beverage companies, and subscription services. When businesses are growing in complexity and need to upgrade their shipping operations, this is where a warehouse shipping solution can help.

For ecommerce businesses, improved efficiency from warehouse shipping software can be especially helpful for remaining competitive. Rapid delivery times and transparent tracking systems are common customer expectations and 68% of customers say fast shipping can lead them to place an order online, according to Flexe.

Who are the end users of warehouse shipping software?

The types of end users include shipping station workers and warehouse managers. They are the workers responsible for entering shipping information, selecting the correct shipping service, printing shipping labels and labelling the packages for shipment. When you are considering new software for your warehouses, it is essential to keep these people front of mind.

What is a warehouse management system?

A warehouse management system (WMS) is also a software program for warehouse operations, and it helps workers easily locate items in the warehouse. With features such as mobile barcode scanning, inventory management, multi picking strategies, and data analytics, a WMS facilitates faster and more accurate picking and order fulfillment. Like shipping software, it increases efficiency while reducing operational costs.

How do a WMS and shipping software work together?

While warehouse shipping programs can function without a WMS, many warehouses prefer to integrate both solutions. In fact, some businesses run warehouse shipping software on the backend, leveraging automation rules to select services and print labels from the frontend WMS interface within the picking workflow.

For example, a manager can build business rules to enable automatic rate shipping and apply the cheapest expedited shipping service to each order. Instead of expecting shipping station workers to manually complete these tasks, the automation rules can run in the background. The shipping software works behind the scenes to print the correct labels as pickers scan barcodes on the warehouse floor.

Do I need warehouse shipping software?

If you operate at least one warehouse and struggle to pack and ship orders efficiently while controlling costs, it may be time to invest in warehouse shipping software.

How many of these common shipping problems are you currently facing?

Paper-based processes

Are you still using physical copies of orders, handwritten labels, notes, and checklists, paper-based inventory and records? Papers can easily get disorganized, damaged, or lost, leading to inefficiency and errors. Plus,

Shipping is too expensive

In a recent ecommerce consumer sentiment study sponsored by Descartes, 83% of online shoppers rated shipping cost as extremely important. When customers expect low-cost or free shipping, businesses must find ways to absorb shipping costs while remaining profitable. Shipping software can help you cut costs, and we will provide more details about this later in the article.

Struggling to keep up with orders

If there is a backlog at the shipping station or workers frequently miss the daily carrier pickup time, then it’s time to consider using software to keep up with the orders. Late deliveries and unhappy customers are also signs that warehouse shipping software could be needed.

You may gain a competitive advantage by using a shipping solution to solve this problem. More than 80% of warehouses globally do not use any form of automation according to Meteor Space, so implementing shipping software with automation rules to speed up shipping workflows may give you an edge.

Slow manual shipping process

Warehouse shipping software could be needed if workers are manually typing address information into a shipping program, manually selecting the shipping service, or handwriting shipping labels. Even with a large workforce, it would take significantly longer to process these orders at the speed warehouse shipping software can.

Warehouse shipping software can automatically generate these shipping labels for you, and your warehouse team will only need to attach them to packages before sending them out to the carrier. This will allow the team to buy back valuable time for other tasks.

Disconnected software programs

If workers are logging into multiple shipping carrier programs and multiple sales channel platforms, then this is another sign warehouse shipping software may need to be used. This could lead to double data entry and key-entry errors, slowing down the process. Logging into multiple carrier accounts also makes it harder to rate shop and find the best deals.

Missing or disorganized tracking info

If the quantity of orders is too much for a team to handle, it’s easy to lose sight of tracking information and miss out on timely communication with customers. Packages could go missing and nobody would be aware where the package disappeared. Without real time notifications for packages, unhappy customers are more likely to be constantly asking, “where’s my order.” Luckily, this can be avoided by using shipping software.

How does warehouse shipping software reduce costs?

Let’s dive into some of the ways you can save money on shipping by using warehouse shipping software.

Increased efficiency

Thanks to the increased efficiency, warehouse shipping solutions can help reduce labor costs, expensive errors, and paying more for expedited shipping to avoid late deliveries. Instead of requiring personnel to manually complete shipping tasks, the software automates order import, rate shopping and service selection, label printing, tracking info notifications, and more. This leads to increased overall productivity, fewer errors, and lower labor costs.

Access discounted rates

Multi-carrier shipping solutions often provide deeply discounted carrier rates, allowing businesses to save money on shipping labels. Some shipping software includes pre-negotiated discounted rates with up to 89% off retail prices. It also makes faster shipping services more affordable, giving businesses a more cost-effective way to provide 1–2-day shipping.

Real-time rate shopping

Real-time rate shopping can help businesses reduce shipping costs by finding the most affordable shipping service that meets the delivery requirements for each order. The software displays shipping rates from multiple carriers and allows shippers to rate shop for a single order or a batch. It can also automate rate shopping according to customizable business rules that include other factors, such as preferred carrier or delivery speed.

Reduced manual labor

Shipping software can automate recurring tasks, boosting productivity and reducing labor costs. This frees up employees to focus on other tasks in the business. Some tasks that can be automated include printing labels, selecting service level or packaging type, rate shopping, picking the cheapest or fastest shipping mode, and sending tracking information to customers.

What are the best warehouse shipping software brands?

Considering using warehouse shipping software for your business? Some popular software providers include:

Key Takeaways

- Warehouse shipping software provides advantages for midsized businesses by facilitating faster shipping, greater throughput, lower operational costs, and increased efficiency.

- This type of software solves common shipping problems such as backlogs, late orders, missing the daily pickup time, high shipping costs, logging into multiple programs, and misplacing tracking information.

- Shipping software is not the same as a warehouse management system (WMS), though the two programs should work together to provide seamless shipping and fulfillment workflows.

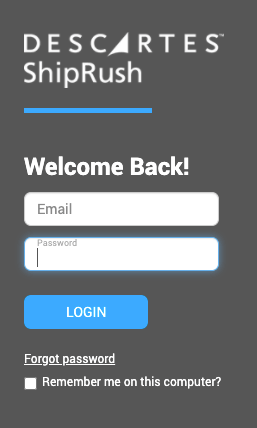

Can I see a shipping software demo?

Descartes ShipRush is a powerful warehouse shipping software that integrates with Descartes Peoplevox™, the ecommerce warehouse management system (WMS) for growing DTC brands, enabling pick-pack-ship and more.

Are you ready to see warehouse shipping software in action? Request a free demo of Descartes ShipRush today.

About the Author

Johannes Panzer is the Head of Industry Solutions for Ecommerce at Descartes. With over 17 years in ecommerce fulfillment and shipping SaaS, Johannes brings a wealth of experience in uniting ecommerce business leaders with the right tools and techniques to overcome logistics challenges and drive profitable growth.