Today’s ecommerce customers have high expectations. They’re looking for their online shopping experience to include: fast shipping, visibility, the best prices, easy returns, and continuous communication from order confirmation to the proof-of-delivery (POD). These customers understand that if they are unable to have their expectations met by one online retailer, there are a myriad of others available to them.

Ecommerce businesses feel the pressure of increased customer expectations and can become overwhelmed while trying to keep up. In order to thrive in this competitive environment, we need to get fulfillment processes right. While the phrase “Pick, Pack & Ship” is often used to describe the warehouse processes for larger operations, all ecommerce businesses (including SMBs) can benefit from more efficient order fulfillment.

Use Chaotic Storage to Pick Orders Faster

The typical approach to organizing a warehouse is to group similar items. However, this practice does not make the best use of space. For example, organizing by product type does not mean that the related items will fit in a given space without time-consuming reorganization and that fast-moving items are placed within easy reach to maximize picking productivity. Employees often end up on “treasure hunts” trying to find the right item.

A chaotic storage approach fills free space more quickly and is more efficient in using space. Chaotic storage involves using a warehouse management system (WMS) to direct the put away of items in what appears to be a random fashion to minimize put-away time. The WMS then efficiently manages the picking process because it knows where all items were placed, and it guides pickers to the right location in a logical way.

The key takeaway from the chaotic storage model is to look closely at your storage methods and think critically about whether a WMS-directed operation is a more efficient way to store and handle merchandise.

Single vs. Multi-order Picking Strategies

All ecommerce businesses can now use efficient picking strategies that used to only exist in larger warehouse operations. Here’s how to improve picking productivity.

- Single-Order Picking

This is the classic scenario where an order is simply picked, packed, and shipped. For small businesses, this may be perfectly fine. As a business grows, however, individual order fulfillment becomes more and more labor intensive and inefficient. - Multi-order Picking

In this model, a worker is guided by the WMS to pick items for multiple orders at once. Workers are directed to pick orders that have items clustered closely together in the warehouse. Toward the end of the process, orders are consolidated, packed, and shipped.

Provide Real-Time Customer Updates on Order Status

In today’s competitive environment, it is critical to offer customers visibility during the entire purchase lifecycle to enhance the customer experience and build delivery confidence. Best-in-class warehouses and online retailers offer full and accurate stock availability as well as continuous fulfillment statuses from picking through proof-of-delivery. One example is branded tracking pages and emails. Leading ecommerce fulfillment solutions offer ecommerce businesses the connectivity, automation and communication capabilities to help inform and delight customers.

Automate Shipping Service Level & Carrier Selection

Manually selecting the right service level and finding the most cost-effective carrier can be a complex job. The size and weight of a package, destination address, and other factors can substantially impact label prices. How can shippers reduce complexity and control shipping costs?

Many ecommerce companies have discovered that using multiple carriers, rate shopping, and comparing service levels are the best way to minimize costs and better meet consumer needs. Choosing the right carrier and service can feel challenging, especially as the volume of orders increases. Leading ecommerce companies use shipping automation rules that determine and select the the fastest, cheapest shipping option and print one-off carrier labels or batches to support the fulfillment process.

Build a Tech Stack for Pick, Pack & Ship

Ecommerce businesses are complex operations with many moving parts and functions happening simultaneously. In this environment, it can be challenging to know where to focus productivity improvements and determine where optimization efforts will pay off. Your best bet is to focus on the elements of the fulfillment process that affect the customer directly, such as pick, pack, and ship processes.

Ecommerce pros optimize the entire fulfillment process by building an ecommerce tech stack. These integrated solutions connect their sales channels, streamline fulfillment operations, improve productivity, continuously engage the customer, and support a path for long-term growth.

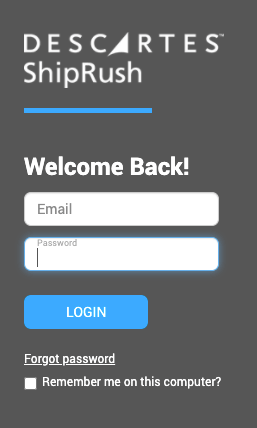

We’re here to help.

Descartes ecommerce solutions provide an end-to-end-ecommerce fulfillment platform. From sales channel connectivity to order and warehouse management to shipping, we can help you increase efficiency and save money in ecommerce operations. If you are looking to have a conversation about how Descartes can help your ecommerce business succeed, our experts are standing by.